Rutting problem in Vietnam

Rutting Problem in Vietnam

(This paper is the re-edition of what I have done at Kyoto

University/UTC joint summer seminar held in UTC.)

October 6, 2015

Dr. Hiromitsu NAKANISHI

TAIYU Kensetsu Co., Ltd

Back ground

In Vietnam, rutting problem becomes very serious recently along with increase in maintenance area of national roads. Furthermore, the rutting would be arising in early stage just after construction. Now, the clarification of the cause and the countermeasure have been urgent issue for universities, government, and construction companies, MOT has been addressing earnestly with this issue.

However, what I want to know for this issue are;

(1) To the best of my knowledge, rutting was hardly seen although there were many cracking and potholes on National road route-1 about 3 years ago. Why do the recent pavements have the problem with rutting?

(2) Even at the same construction site and even on the same lane, there are severe rutting at some parts while the other parts are sound. This can’t be explained by only heavy traffic or by only hot temperature.

(3) There are no general tendency for the location of occurrence of rutting in Vietnam, although severe rutting are often seen in front of intersection in Japan. Severe rutting arises even on normal passing lanes. Why?

(4) At early stage just after construction, bleeding and flushing arise firstly before rutting. These bleeding and flushing are very serious. This means that VFA is getting larger. However, there are sound parts in which bleeding and flushing don’t arise on the same lane. Growth process of rutting in Vietnam is very characteristics. It proceeds along the almost same process, in which rutting is accompanied by bleeding. In general, rutting is not always accompanied by bleeding. If anything, rutting in Vietnam is primordial and primitive. Why?

(5) It looks like rutting is arising anywhere in Vietnam, North region, Middle region and South region. This means that rutting problem is arising regardless of the aggregates’ kind, like lime stone,

granite, and basalt. It might be due to how to design the asphalt mixture. Based on the knowledge mentioned above, I’m sure that there should be something worse in the asphalt mixture itself. This report is originally based on the presentation which I have done for Kyoto University/ UTC joint summer seminar held on 23 October at UTC. And this report is focused on rutting problem occurring in Vietnam

1. Geography in Vietnam

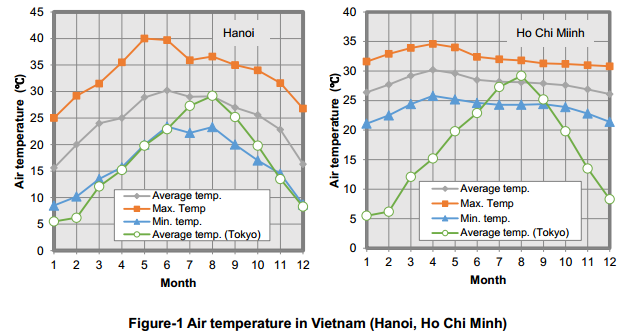

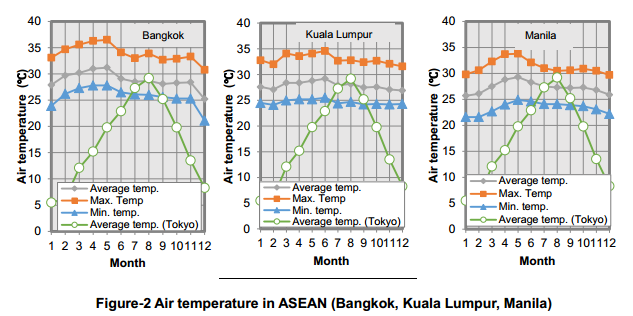

What impact directly on rutting are temperature of the pavement and the number and weight of the wheel load of tracks. Although I have no information about the traffic weight and traffic number, these might not be direct causes on rutting because there are rutting parts and un-rutting parts even on the same lane as mentioned above. The data on the temperature in ASEAN countries are shown in Figure-1.2.

According to Figure-1 and 2, air temperature in Vietnam is not always higher than other ASEAN countries, Air temperature in Hanoi is rather lower than other ASEAN. However, as far as I know, I have never heard that very severe rutting is arising in other countries. That is, the outer factors like traffic weight and temperature would not be the special cause. As a result, we will be able to understand there is the true cause of rutting in Vietnam in inner factor, like the asphalt mixture itself.

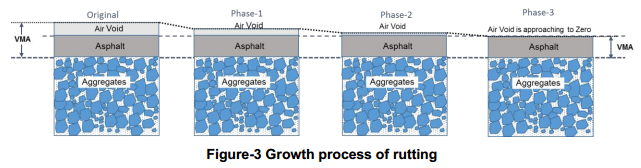

(1) Phase-1

This is a picture I took at Phap van-Cau Gie on national road route-1. Although these pavement has

been executed at almost same time, bleeding is seen on driving lane while there are no bleedings on passing lane. The occurrence of bleeding and flushing means that VFA, namely aggregate voids filled with asphalt, is becoming higher. Increase in VFA means VMA, namely voids of mineral aggregate, is becoming smaller because asphalt volume would not be able to be changed

(2) Phase-2

(2) Phase-2

This is a photograph of Phase-2. In Phase-2, the bleeding and flushing proceed further, the rutting

begins arising. The growth process of rutting, in which the bleeding is proceeding and is connecting

to rutting, is representative in Vietnam.

(3) Phase-3

Phot-3 is a photograph of the pavement on Thanh-Chi Bridge. This is Phase-3. In this circumstance, the air void percentage becomes almost 0% and VFA becomes almost 100%. Probably, even though some modified asphalts have been employed for this pavement, the interlock effect by stone to stone contact would not be able to work efficiently in such situation.

(4) Growth process of rutting

Here, the growth process of rutting is put together.

Phase-3 is the final and worst stage. The voids among aggregates have been filled with asphalt, the dry contact between aggregates has been lost. It means the dry interlock effect among aggregates can’t be expected. Figure-3 looks to show that the air void percentage has become smaller. As for the actual phenomenon occurring on site, it would be correct, but it wouldn’t be correct in terms of the direct cause. VMA has become smaller by traffic loads. We should understand that VMA becomes smaller at first and VFA becomes higher secondly and bleeding arises as a result. That is, decreasing in VMA is a primordial cause of the rutting which arises just after construction and is becoming serious issue in Vietnam. Therefore, it is most important for us to consider why VMA would be smaller and how we can address this problem to solve rutting problem.

3. Specification of HMA

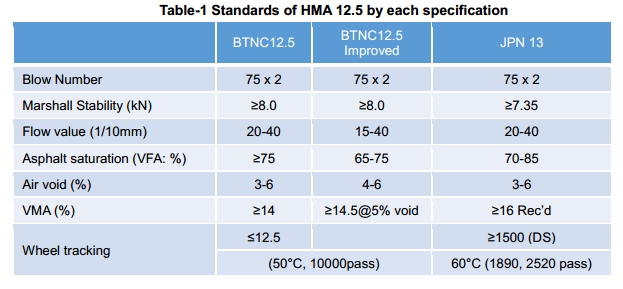

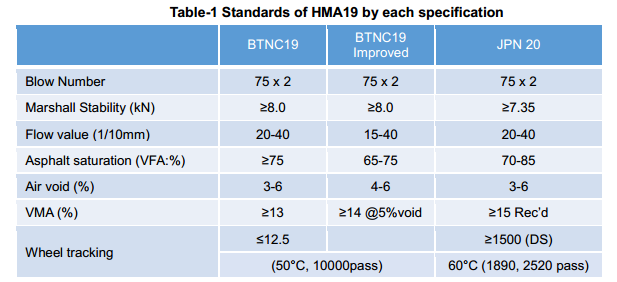

I will compare the specification of three types, namely, BTNC, BTNC improved by decision 858, and

Japanese dense graded.

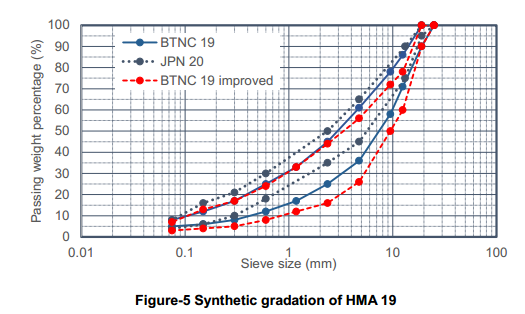

Firstly, the gradation range of BTNC 12.5, secondly BTNC12.5 improved by Decision 858, and JPN13. The gradation range of BTNC12.5 improved is the coarsest. The gradation ranges of BTNC 12.5 and JPN13 are relatively similar. Next, I will compare the specification of each asphalt mixture. They are almost similar, but we need to focus on the specification about VFA and VMA of each mixture. The specification of VFA has been revised and lowered rather than BTNC 12.5, and VMA in Vietnam is still smaller than that in Japan.

Regarding the gradation range, that of BTNC 19 improved by Decision 858 is becoming much coarser than original BTNC 19. It is significantly coarser than JPN 20. Regarding the specification of the mixture, we need to focus on VFA and VMA, as well. As for VFA, we can control it by changing asphalt content, but we might not be able to change VMA because VMA depends upon the mix proportion of aggregates used. Even though VMA of BTNC19 improved is 14% or more, it is still smaller than that in Japan. The difference is at most 1% to 2%, but what the difference means is very important. I’m convinced that there is important relationship between rutting and VMA. In my experiences in Japan, VMA should be generally 16% to 17%.

4. Let’s think about VMA

(1) What do you think arises when VMA is smaller?

Firstly, optimum asphalt content tends to decrease. It looks like the asphalt content of the asphalt mixture with VMA of about 14% is about 4.5% in Vietnam. In comparison with that, the asphalt content of the asphalt mixture with VMA of about 17% seems to be from 5% to 5.5% in Japan. Decreasing in asphalt content would benefit economically, and it might contribute to improvement in rutting resistance only for the initial stage. However, we need to take a risk that cracks and potholes would arise instead of rutting, just as if they had arisen on the route-1 before maintenance. Secondly, VFA would become easy to rise when VMA is smaller. VMA is a space in which asphalt exists. That is, in case of smaller VMA, if it becomes smaller by the traffic loads, VFA would go up sensitively. As a result, the bleeding and flushing come up, and the plastic flow arises easily.

(2) Why do you think VMA tends to become smaller in Vietnam?

The impact by aggregates used would be very big. I think, in detail, the use of screenings, crush dust, must be a main cause. Although we have used the screenings as a fine aggregate in Japan, it would be rare case to use only screenings. We used screenings together with other fine aggregates, like mountain sand, river sand, crushed sand, slag sand, and recycled aggregate. I’m sure VMA becomes smaller when only screenings is used for a fine aggregate. To make matters worse, the size of screenings in Vietnam is from 4.75mm to 0 mm. On the other hand, Japanese screenings has the size of 2.36mm to 0 mm.

5. Present situation of HMA production

Raw stones are crushed by crushers using jaw crusher, impact crusher, corn crusher, and others. In

general, aggregates crushed will be classified into each single size, and they will be used as materials at asphalt plant. This means that asphalt mixture is re-produced using each aggregate

made of the same raw stone. Therefore, this asphalt mixture would be easy to be compacted and it

would cause the smaller VMA.

6. Comparison of HMA which has been generally being used in VN and JP.

BTNC 12.5 and BTNC 19 are popular in Vietnam. In Japan, Dense graded 13 and 20 are popular although there are some kinds of HMA used for surface course in Japan. Here, I would like to compare BTNC19 and JPN20, which is dense graded HMA.

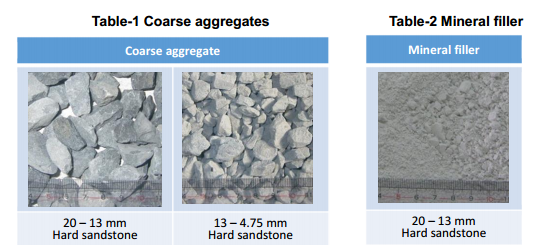

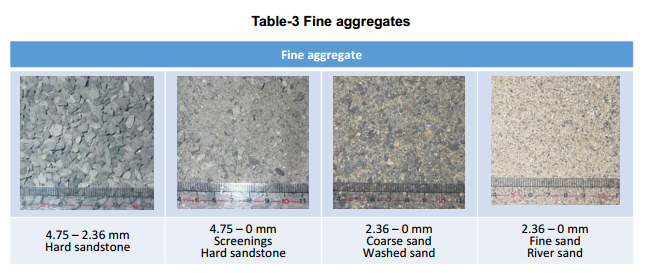

(1) Materials used

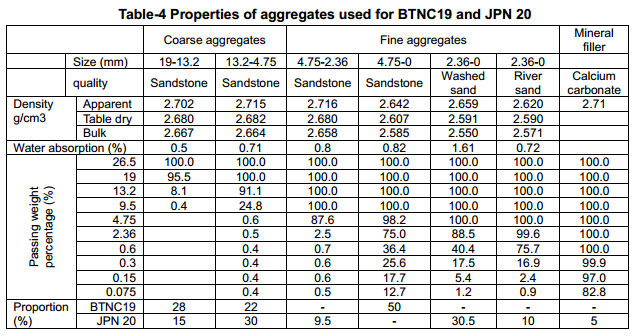

The classification of the size of aggregates is different between Vietnam and Japan. That is, aggregates with the size of more than 4.75mm are classified as coarse aggregates, and aggregates with the size of less than 4.75mm are classified as fine aggregates in Vietnam. On the other hand, the boundary between coarse aggregates and fine aggregates is 2.36mm in Japan. Therefore, regarding screenings, the size is from o to 4.75mm in Vietnam while that is from 0 to 2.36mm in Japan. Here, according to Vietnamese rule, aggregates are classified as shown in Table-1, 2, 3. These aggregates are made in Japan. The screenings has been produced specially so as to meet Vietnamese standard, 0 mm to 4.75mm

(2) Materials uses and mix proportion for BTNC 19 & JPN 20

Gradation and density of each aggregate are shown in Table-4. Using these aggregates, mix proportion for both of BTNC19 and JPN 20 are designed. Each mixture is designed to meet each specification about gradation. Only screenings is used for BTNC19 as a fine aggregate. But, this screenings was too fine to use calcium carbonate as a mineral filler. On the other hand, the mix proportion for JPN20 is as shown here. Some kinds of fine aggregate are employed together.

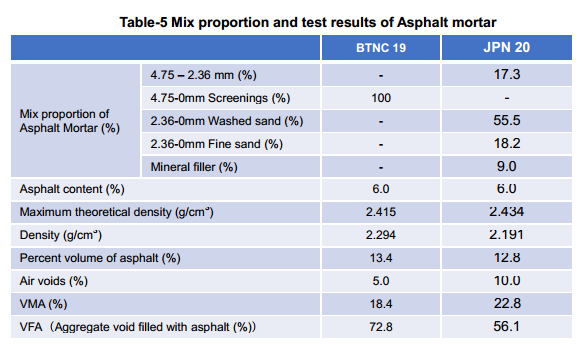

(3) Impact of asphalt mortar on VMA of HMA.

I’m sure VMA of the HMA would depend much upon VMA of the asphalt mortar which constitutes the HMA. Because the voids among coarse aggregates are generally filled with asphalt mortar.

Here, I would like to confirm the difference of VMA of the mortars used for BTNC19 and JPN 20. The mix proportion of each asphalt mortar is based on the mix proportion of each HMA of BTNC 19 and JPN 20. Therefore, the mix proportion of each mortar is as shown in Table-5. Furthermore, test

results are shown in Table-5, too.

Note) Asphalt content of both mortar is decided to be same as 6%. VMA of mortar from BTNC19 was 18.4%, and that of mortar from JPN20 was 22.8%, the difference was very big like 4.4%. VFA of BTNC19 was 72.8%, and that of JPN20 was 56.1%. The difference is very big like 16.7%. These test results show that use of only screenings results in smaller VMA and higher VFA, compared with the case to use some kinds of fine aggregates together.

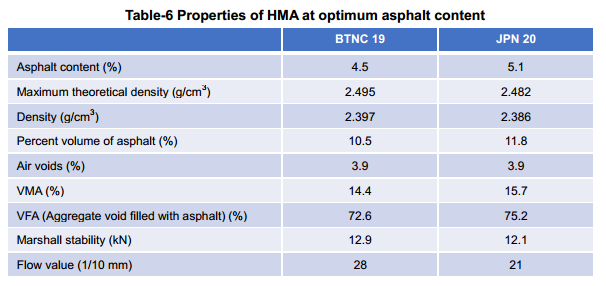

(4) Mix design of each HMA, BTNC 19 and JPN 20

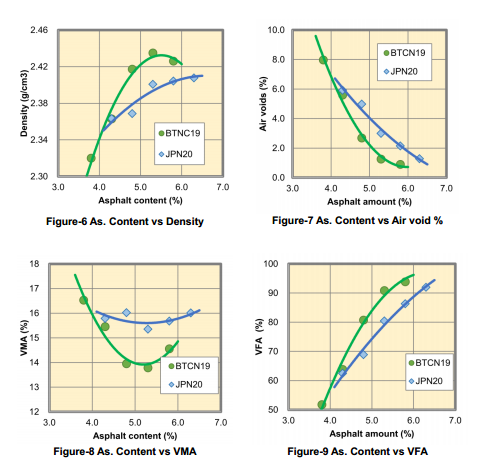

The test results of Marshall Test for BTNC19 and JPN20 are shown in Figure-6 ~9.

First of all, we all would find that all of curve of BTNC is steeper than that of JPN 20. This shows that the behavior of BTNC 19 to the change in asphalt content is much more sensitive than that of JPN 20, and this means that the change in the properties of BTNC 19 is very large even though the change in asphalt content is very small. We should focus on the data about VMA. The absolute difference of VMA between BTNC 19 and JPN 20 is about 1.5%, but VMA of BTNC 19 is decreasing by about 2.5% along with the increase in asphalt content of 1% while that of JPN 20 is not almost changed. The difference in the behavior of VMA would be brought from the difference in VMA of asphalt mortar. The same tendencies are seen in the graph on density, air void percentage, and VFA. Table-6 shows the properties of each HMA at optimum asphalt content.

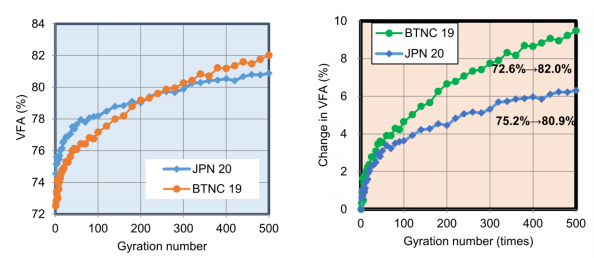

Regarding VMA and VFA, there are some differences between BTNC19 and JPN20. In general, the properties of asphalt mixture should be changing by receiving the repeated traffic loads. In order to see the change in the properties of asphalt mixture, we have carried out next experiment.

7. Impact of properties of HMA on repeated traffic load by Gyratory Compactor

(1) General

We sometimes employ the evaluation test which shows the influences by repeated traffic load, like

wheel tracking test. However, the wheel tracking test is specialized to rutting, especially plastic flow.

Now, we need to look into the change in some properties of HMA while the asphalt pavement has

been subjected to the repeated traffic load. In order to do that, we try to employ Gyratory compactor

machine. Gyratory compactor has a merit that the change in density of HMA can be obtained along

with a gyration.

(2) Test procedure

The procedure of this trial is as follows;

1. To produce asphalt mixtures at 165 °C.

2. To put the asphalt mixture in a mold.

3. To compact the asphalt mixture by a gyratory compactor at 145°C until the thickness would become 6.35cm.

4. To take the mold out of the gyratory compactor.

5. To keep the specimen in the mold for 6 hours or more at 60°C

6. To re-compact the specimen in the mold by the gyratory compactor at 60 °C again.

7. To record a density (height of specimen) change of each specimen.

The test conditions are as shown in Table 7. The Gyratory compactor which we have has a limitation of gyration number, it is 500 gyration. Therefore, therefore, we have carried out this trial to 500 gyratory. The test results are shown in Figure-10~13.

(3) Test results

To the best of my knowledge, such trial using Gyratory compactor is probably new one.

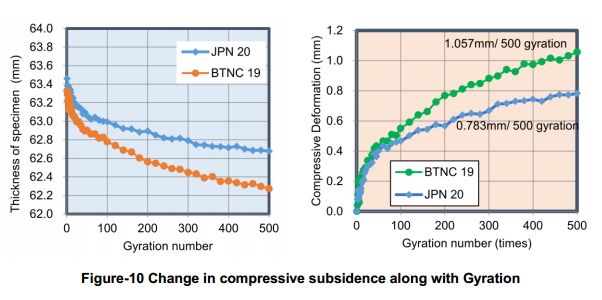

The data on change in thickness is original data obtained by Gyratory test. Especially, the left side figure in Figure-10 shows the raw data. The initial thickness of specimen are 63.46mm for JPN 20 and 63.33mm for BTNC 19, respectively. After 500 gyration, the thicknesses of specimens of JPN 20 and BTNC 19 are 62.68mm and 62.27mm, respectively. Summarizing these data, BTNC 19 sags by 1.057mm while JPN 20 sags by 0.783mm during 500 gyration. Compressive stress of this gyratory compactor is 600kPa, about 6.12kg/cm2, and it is almost same as the tire pressure of vehicles. The difference of compressive subsidence after 500 gyration between BTNC 19 and JPN 20 is significantly bigger rather than expected.

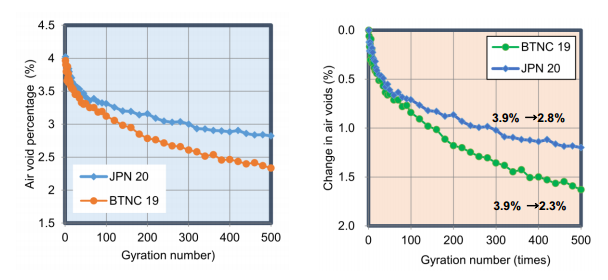

Figure-11 Change in Air void % along with gyration

Figure-11 shows the change in air void percentage. As a matter of course, the air void percentage is

related to the thickness of the specimen. As a result, although the initial air void percentage is 3.9%

for both mixture, after gyration, the air void percentage of BTNC 19 has shrunk to 2.3% while that of

JPN 20 has shrunk to 2.8%. Only 500 gyrations resulted in the thus big change in the air void

percentage.

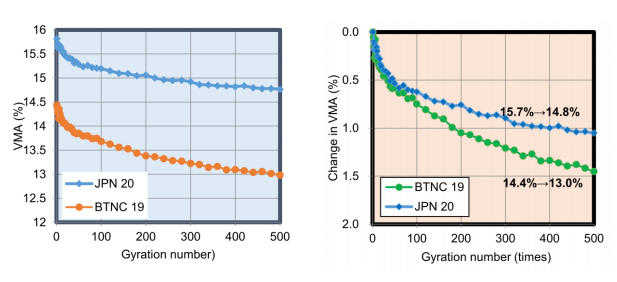

Figure-12 Change in VMA along with gyration

It is true that the air void percentage is becoming small. But, it’s just a result of the deflation of VMA. It is very important things to understand that the change in the air void percentage is not the cause but the result and the change in VMA is not the result but the cause. That is, the decrease in VMA results in the decrease in the air void percentage. The initial VMA is different, that of BTNC 19 is 14.4%, and that of JPN 20 is 15.7%. Basically, it is very important to consider why the difference in the initial VNA has been born between both mixtures. But, here, we are going to focus on the change in VMA. After 500 gyrations, VMAs of BTNC 19 and JPN 20 have shrunk to 13.0% and 14.8%, respectively. The changes during 500 gyrations are 1.4% and 0.9%, respectively. In fact, the magnitude of the change of BTNC 19 is significantly bigger than expected.

In fact, the change in VFA arises as the result of the change in VMA. It’s the same as the air void percentage. I would like you to remember that I formed the hypothesis that VMA would become

smaller for some reason and small VMA results in increase in VFA and higher VFA results in bleeding and bleeding brings the plastic flow, it is rutting. The initial VFA of BTNC 19 is 72.6%, but VFA is increasing to 82% after loading of traffic weight. Even though the initial VFA is relatively low, as far as BTNC has the characteristics that it is easy to be compacted, VFA after loading is growing higher abruptly. According to the specification improved by Decision 858 in Vietnam, VFA should be from 65% to 75%. Even though the initial VFA is relatively low, after receiving the traffic loads, VFA is abruptly rising and it results in bleeding because the rate of rise in VFA of BTNC19 is about double faster than that of JPN20. There should be something we have to review drastically and fundamentally to solve the rutting issue in Vietnam. Superficial revisions would not reach to the fundamental solution and would bring the risks that cracking and potholes might arise widely in near future. Anyway, I think this test result represents well the practical phenomenon of rutting in Vietnam.

8. Conclusion.

Regarding the growth process of the rutting, firstly, the bleeding and flushing appear by receiving traffic loads. The bleeding and flushing in Vietnam are easier to arise than in Japan Secondly, I think the cause must be smaller VMA. Finally, I think the cause of smaller VMA must be use of screenings as fine aggregate. In my presentation, facts and imagination are mixed together. But, I think it must be better not to use only screenings or screenings as it is as a fine aggregate. This is my proposal to rutting problem in Vietnam. I would be really pleased if you could refer to my presentation and look into deeply the cause of rutting again.

Other posts